Enhance Your Fibre Optic Projects With an Effective Diameter Analyser

The integration of a reliable diameter analyser right into fiber optic tasks serves as a crucial element in accomplishing accuracy and consistency. By helping with exact size dimensions, these analysers not only boost the top quality of installments but likewise minimize potential compatibility concerns amongst components.

Relevance of Size Dimension

Determining the diameter of fiber optic cable televisions is a crucial job that ensures optimal performance and dependability in communication systems. Precise size dimension is essential for different factors, largely for maintaining signal honesty and lessening loss. A cable's size straight influences its ability to transmit light efficiently; inconsistencies from the defined diameter can bring about enhanced attenuation, which affects the general efficiency of the network.

Moreover, exact dimension is vital throughout the setup and upkeep of fiber optic systems. An improper fit in between wires and adapters can lead to signal degradation or full failing of communication links. By guaranteeing that diameters are within specified resistances, service technicians can enhance compatibility between parts, causing better system reliability.

Furthermore, diameter dimension plays a significant function in high quality control during production. Consistency in the size of fiber optic cable televisions is crucial for ensuring uniform efficiency throughout different batches. optical fibre diameter analyser. This consistency aids suppliers maintain industry criteria and fosters confidence amongst end-users

Functions of an Effective Analyser

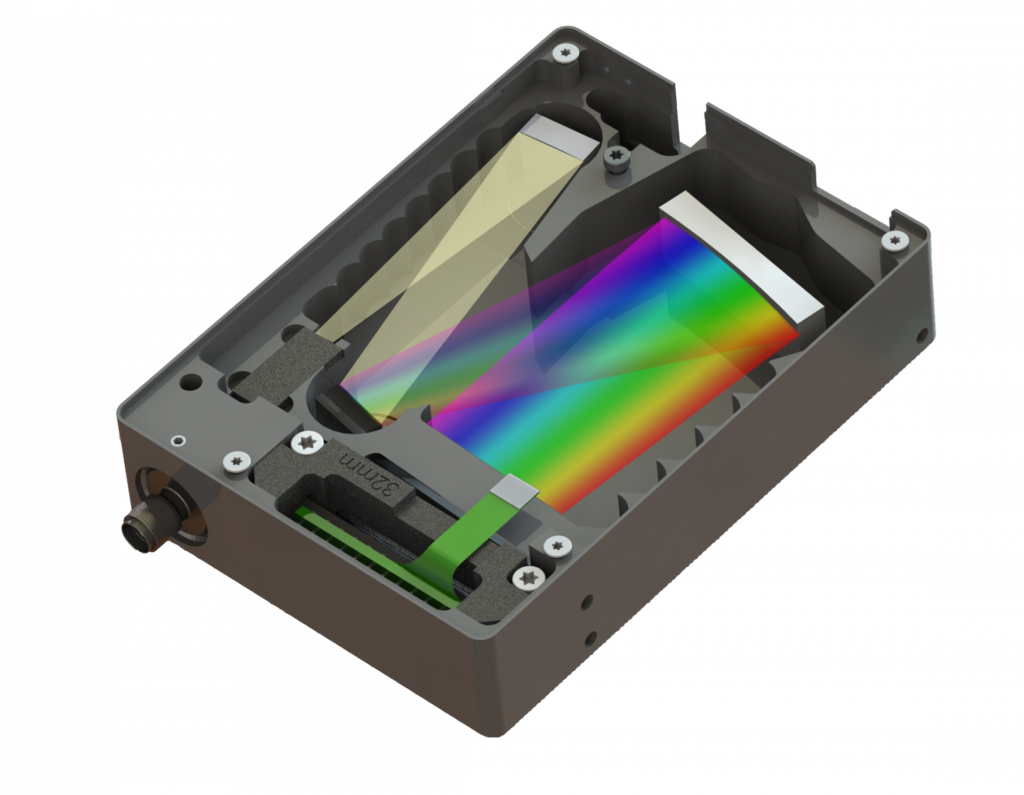

An effective analyser for fibre optic tasks should include a number of key features that improve accuracy and use in diameter measurement. First of all, high-resolution optical sensors are essential for accurate diameter analyses, allowing users to detect even the tiniest variations in fibre density. These sensing units need to be matched by sophisticated calibration systems, guaranteeing constant performance throughout different problems and products.

Second of all, a straightforward user interface is essential for helping with ease of operation. This includes user-friendly software application that permits for smooth data input and result, together with aesthetic representations of the measurements taken. A portable style improves functionality in numerous field settings, making it easier to carry out assessments on-site.

In addition, the analyser should support numerous measurement settings, fitting various fiber types and applications. The ability to store and obtain historic information is another essential feature, enabling customers to track efficiency with time and make notified choices.

Advantages for Fiber Optic Projects

Implementing a size analyser in fibre optic tasks supplies considerable benefits that substantially boost task efficiency and top quality. Among the primary advantages is the ability to make sure specific measurements of fiber size, which is critical for keeping ideal performance in fibre optic systems. Accurate size readings assist in the identification of disparities that might result in indicate degradation or loss, therefore making certain top quality transmission.

In addition, using a size analyser simplifies the quality control process. By automating measurement jobs, task teams can lower the time spent on manual inspections, bring about faster project completion and decreased work prices. This effectiveness additionally permits even more strenuous testing protocols, resulting in improved item integrity.

Furthermore, consistency in fibre diameter dimensions promotes compatibility with other fiber optic elements, decreasing the risk of click here to read installation mistakes and improving overall system efficiency. The incorporation of a diameter analyser not just help in maintaining sector standards yet likewise cultivates confidence in job deliverables.

Integration Into Existing Process

Incorporating a diameter analyser into existing process can considerably boost the operational performance of fibre optic projects. By effortlessly including this modern technology, groups can achieve exact dimensions that are important to maintaining the honesty and performance of fiber optic systems. This assimilation permits real-time information collection and analysis, which can be crucial throughout the manufacturing and installment phases.

Additionally, the capacity to automate diameter measurement procedures minimizes the possibility for human error, guaranteeing consistent quality assurance throughout the task lifecycle. The data generated can be conveniently shared across systems, helping with cooperation among engineers, service technicians, and task managers. This ease of access boosts decision-making and increases project timelines.

Choosing the Right Size Analyser

When selecting a size analyser for fiber optic jobs, it is vital to take into consideration numerous key factors that directly impact dimension precision and functional effectiveness. The resolution and precision of the analyser must straighten with the specific needs of your project. Greater resolution tools can discover minute variations in diameter, which is important for ensuring optimal performance in fiber optic systems.

Next, examine the rate of measurement. For jobs with limited target dates, a size analyser that supplies rapid information purchase can significantly boost efficiency. In addition, consider the analyser's compatibility with existing systems and software application. A smooth assimilation minimizes setup time and minimizes disruptions during procedures.

Another important element is the variety of sizes the analyser can fit. Guarantee that official source the selected device can manage the particular dimensions of fiber optics you are collaborating with, along with any kind of prospective future requirements. Lastly, examine the producer's support and guarantee offerings. Dependable customer support go right here and technical assistance can verify invaluable when looking for or troubleshooting aid. By carefully examining these variables, you can choose a diameter analyser that improves the efficiency and precision of your fibre optic jobs.

Final Thought

In verdict, the integration of an efficient diameter analyser is vital for improving fiber optic tasks. Specific diameter measurements make certain optimal performance and reliability while lessening installation errors. Advanced features promote real-time data collection and conformity with sector criteria, eventually raising the top quality of deliverables. By focusing on the option and implementation of a suitable analyser, project efficiency is substantially improved, leading the means for effective results in fibre optic applications.

A wire's size straight affects its capacity to transfer light properly; variances from the specified size can lead to enhanced depletion, which impacts the overall efficiency of the network.